The sowing of maize - helpful information on seedtime, the seed rate and soil cultivation

“We reap what we sow” – a distinctive motto at a glance, which reflects the important role of the maize sowing.

With sowing you lay the foundation for successful vegetation and your economic success. Many aspects such as Seed rate and Tillage, are decisive here.

Also, the sowing depth grain storage, the underfoot fertilisation and the driving speed of the used machines are factors that must be taken into account.

KWS introduces you to these factors.

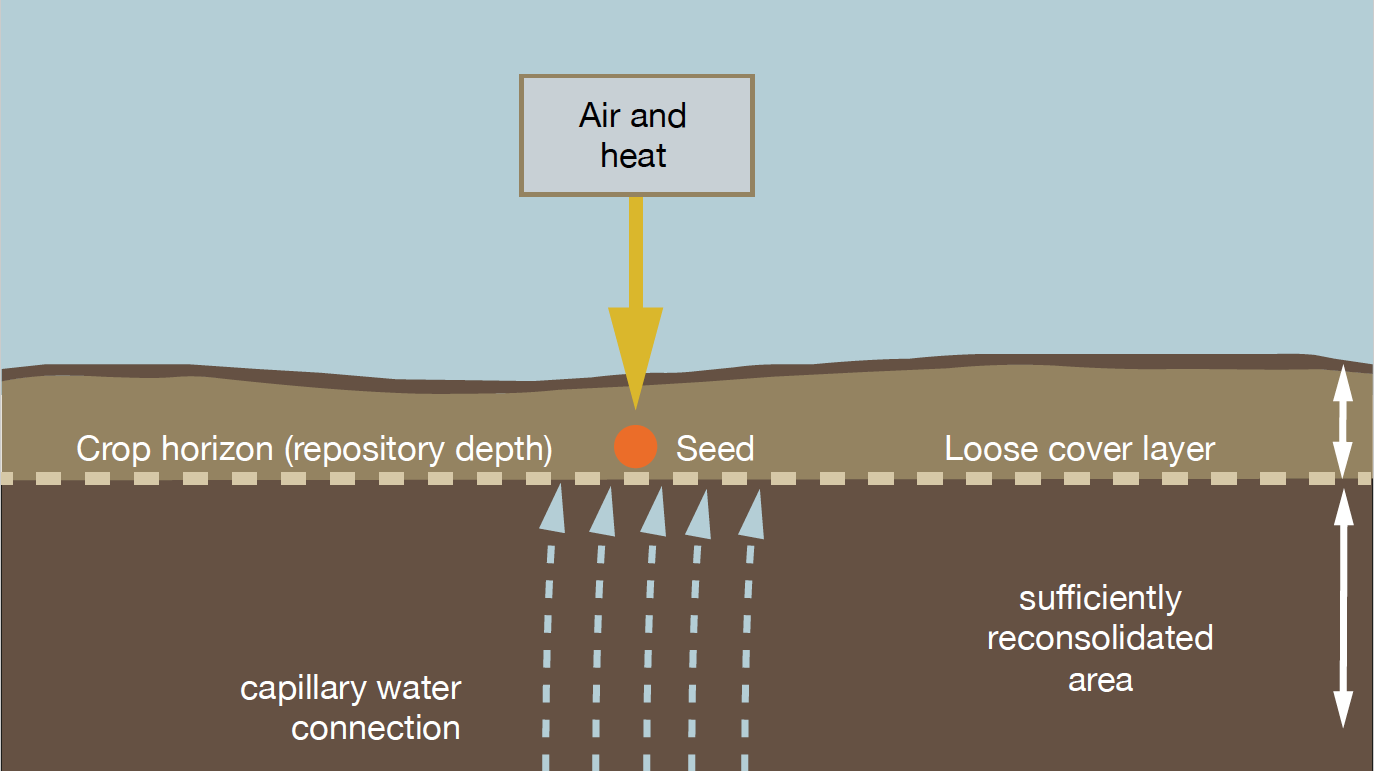

For each crop, the following applies: a constant sowing depth ensures uniform growth. For maize, the sowing depth should be selected so that the seeds are placed in the damp soil horizon .

The capillary water connection must be ensured in every case. Only then can the water required for swelling be absorbed and a high level of field emergence be achieved.

Short and sweet: Rules of thumb for sowing depth

Heavy soils: 4-5 cm

Light soils: 6-7 cm

Too shallow placement = dehydration danger

Deeper placement: Improvement of water availability in dry years, but also more effort = young maize plant is more susceptible to diseases

For early sowing times, a more shallow placement is recommended, since the soil is moist enough, but heat is usually the limiting factor. For later sowing dates, a deeper placement should be selected, since water is the limiting factor.

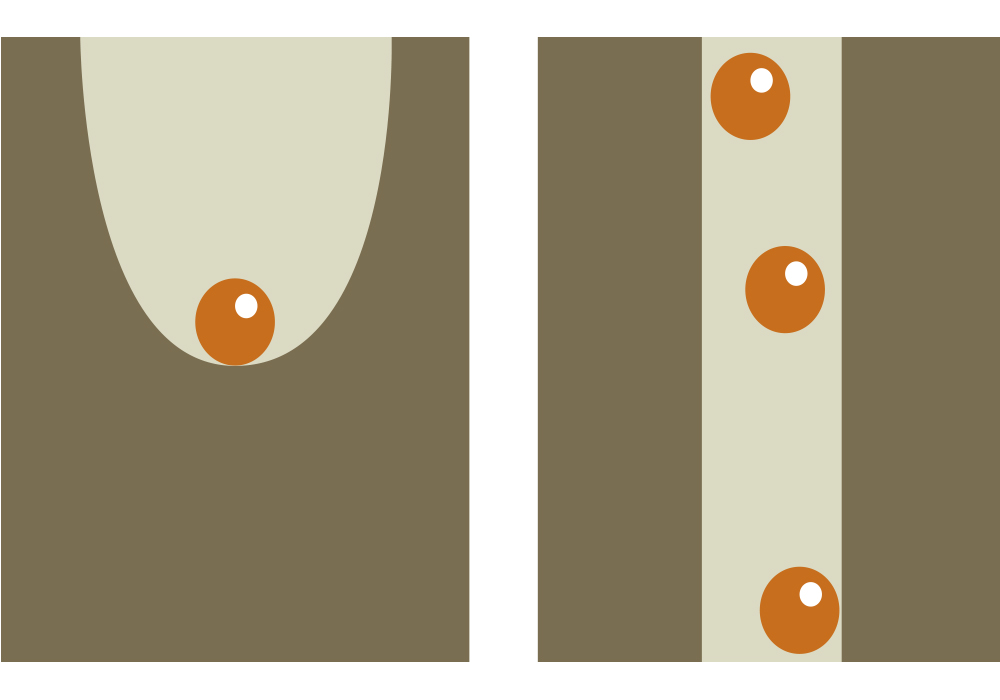

Schematic representation of the seed placement

Maize has in its early development, especially in cold conditions, a poor phosphate acquisition. A deficiency can be best avoided through a placement fertiliser together with an initial nitrogen additive. Here, ammonium-containing fertilisers positively affect the availability of phosphate in the root space by lowering the pH-value.

Various forms of nitrogen fertiliser, and its composition

Source: KWS SAAT SE & Co. KGaA according to LWK NRW

| Fertiliser type | Total nitrogen | Ammonium-nitrogen | Nitral-nitrogen | Other | P205 |

| DAP | 18% | 18% | - | - | 46% |

| MAP | 12% | 12% | - | - | 52% |

| NP (23+23) | 23% | 14.5% | 8.5% | - | 23% |

| KAS | 27% | 13.5% | 13.5% | - | - |

| Entec 26 | 26% | 18.5% | 7.5% | - | - |

| AHL 28 | 28% | 7% | 7% | 14% | - |

| Urea | 46% | - | - | As carbamide | - |

Good experience was also had in the use of liquid N/P-nutrient solutions. The benefits of these nutrient solutions are:

- Storage and application

- flexible adjustment of N/P ratio

- high plant availability of nutrients

- good sensitivity (at approx. 10% water addition)

- supplementation with micronutrients possible

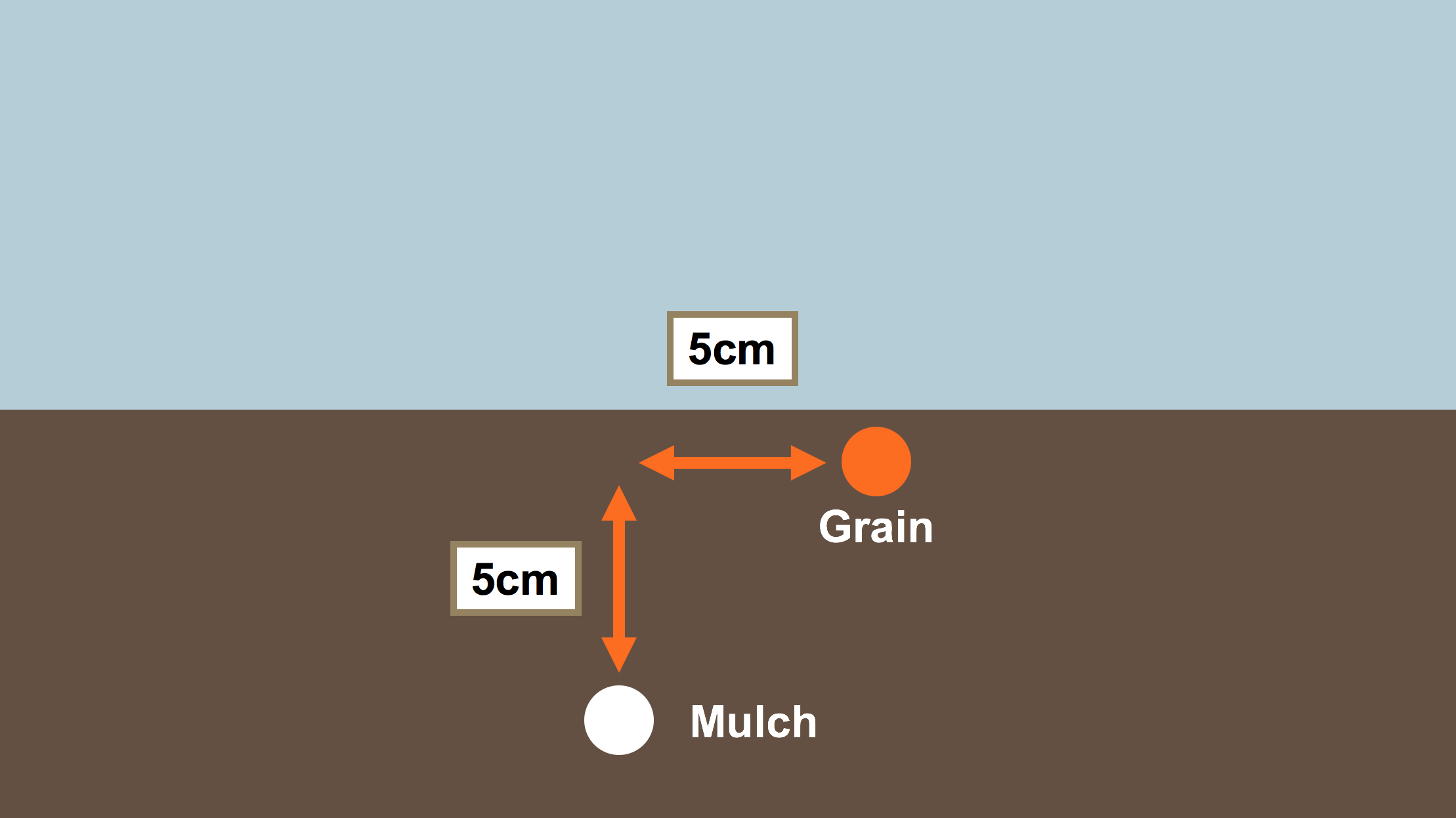

The ideal spatial placement of the fertiliser is important for its effect. The following applies: 5 cm beside and 5 cm below the seed grain.

The placement fertiliser enables the deployment of fast plant-available nutrients in direct proximity to the young maize plant. This will reduce the risk of shortages in the spring, the development of the plant is usually unimpeded.

The following points must be noted for placement fertiliser:

- The fertilisation needs decrease with increasing soil supply

- on light, humus-poor sandy soil, the need tends to be higher due to the poorer nutrient transformation potential than in soils with higher clay content

- for a good availability of phosphates, it is important that the soil structure and the pH-value are OK

- a certain additive via the root fertiliser is useful, especially in order to ensure in rainy springs the additive supply of young maize plants. Usually in the range of 15 to 30 kg/ha N. This nitrogen is to be taken into account in the calculation of the additive fertiliser requirements

- N must be in the form of ammonium

- No chloride in the placement fertiliser. Risk of salt damage, low short-term availability of nutrients

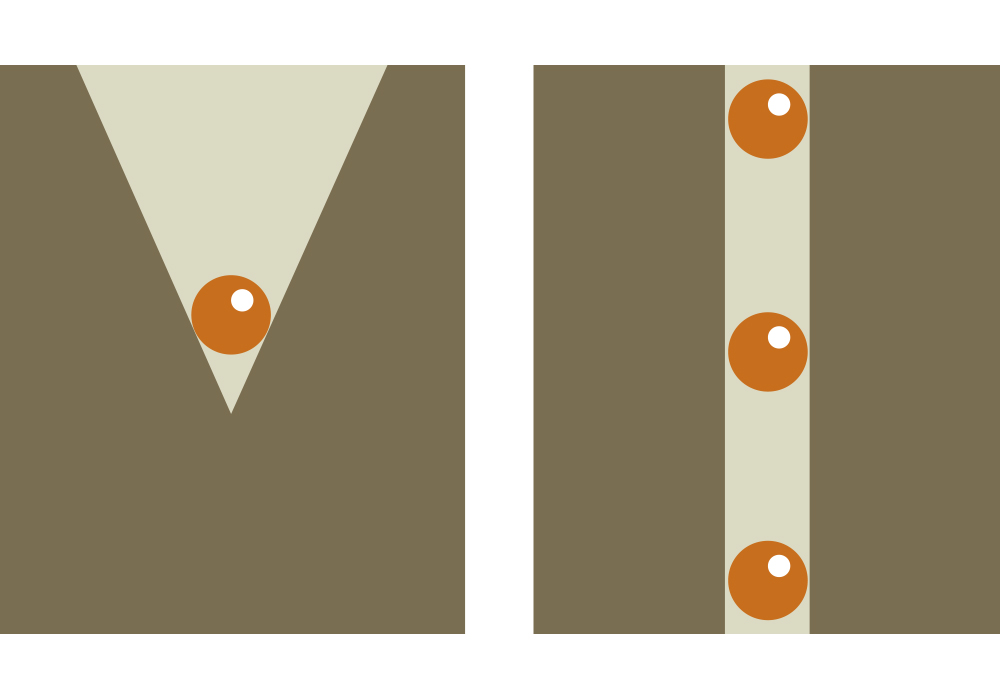

Single seed sowing with a row distance of 75 cm is standard in Germany and has established itself over the years. Nevertheless, both the single seed sowing as well as the row spacings are questioned again and again.

Single seed sowing: the decrease in the row distance from 75 cm (standard) to 45 cm or 37.5 cm offers a variety of benefits, but also various disadvantages.

The benefits are:

- Faster series connection

- Lower erosion risk

- Reduction in evaporation

- Smoother spatial nutrient intake

- Tends to be higher GTM-yield

- Lower late weediness

- Lower residual nmin Contents

The disadvantages are:

- Higher investment costs

- Higher wear

- Higher order costs (around 20%)

- Lower exposure for the cobs and the leaves

- It’s difficult to change from silage to grain maize

- higher amount of root fertiliser necessary

- tend to lower quality in the silage maize

- grain maize harvest more difficult

The approximately 3% higher GTM-yield with less row distance are faced with decreasing strength and energy levels as well as additional technical changes for sowing, care and harvesting. Furthermore, the underfoot fertilisation had to be increased significantly. For 37.5 cm row width, double the amount is necessary to achieve the same nutrient concentration at the seedling as in the case of a row width of 75 cm. This is not the case for ecological and economical reasons.

The drill seed:

The seed drill can currently not fulfil some important requirements of maize. These include: the application of root fertiliser, sufficiently deep placement, consolidation of the seed horizon, compliance with the low sowing rate and the single grain storage. Above all, the different booth space distribution cannot compensate for the maize by lack of tillering. To achieve optimum plant density, the sowing rate must also be increased by approximately 10-15%. The result of the uneven distribution of space are a different young development of the plants and reduced yields.

Benefits include:

- Lower labour time requirement

- Improved machine utilisation

The number of plants per unit area is one of the decisive control options, to exploit the genetic potential of a strain under the given specific growing conditions. With the right plant density, have a significant influence on your growing success.

The general recommendation plant density is dependent on the maturity group and the regional water supply:

| maturity group | Water supply | |

| good | water deficiency | |

| Early (up to 220) | 10-12 Pfl. / m2 | 7-9 Pfl. / m2 |

| Medium early (230-250) | 9-10 Pfl. / m2 | 6-8 Pfl. / m2 |

| Medium late (260-290) | 8-9 Pfl. / m2 | 6-7 plants / m2 |

| Late (above 300) | 8 Pfl. / m2 | 6-7 plants / m2 |

Source: KWS SAAT SE

The optimal number of plants is dependent on the location and the cultivated variety. The weather of the year of production affects the income level is crucial. At very high plant densities, the risk of crop failure is very high under plant densities. Compact varieties or varieties with good drought tolerance can be mounted with a slightly higher plant density.

Good professional practice also includes a vehicle speed customized to the field. Too high driving speeds easily lead to a deterioration of the sowing quality. Consequences are:

- Desired grain number /m² is not reached

- Distribution of grain and depth are inaccurate

- Soil contact and thus the seed germination water supply are endangered

- Imperfections are increasing

Reduced yields and inconsistent seed placement also result even from modern sowing technology.

The condition of the sowing machine is decisive for the consistent storage of seed grain. Therefore, the machine must be inspected before deployment. The following checklist for the use of the sowing machine is helpful to you:

Components to be monitored:

- Sowing coulters: in case of wear, poor distribution and sowing depth (s. figure)

- Furrow closers: uniform coverage of the influx of seed grain

- Sowing depth: Check sowing depth at each individual sowing machine

- Sowing quality tracking

- Fertilisation tracking and dosage

- Underfoot fertilisation coulters: Adjusting the underfoot fertilisation coulter (storage 5 cm sideways and 5 cm below the seed)

- Wheels: Air pressure monitoring (see instructions)

- Drive chains, bearings, overload protection

In addition, check with all pneumatic saw devices:

- Air compressor or turbine

- V-belt tension

- Leading hoses: Tightness

- Air pressure and wipers: Adaptation to grain size and/or weight for each individual unit

- Intake holes: Check cleanliness

- on overpressure devices: Check air intake screen, cyclone separator, air vents

Only through early, systematic checks can deficiencies be tracked relatively easily and hints for the future optimisation of production technology gained. It must be distinguished between a bad field emergence on partial surfaces and large poor ascent.

Poor field emergence on partial surfaces:

- Soil deficiencies (reduce moisture, compression, tracks)

- large differences in temperature on dry and light soils,

- different water availability

- Crows, jackdaws, pigeons, pheasant grub

- Wireworm

Large unsatisfactory emergence:

Basically, an unsatisfactory emergence is when over 10% of the seedlings are missing. The appearance and the causes for a large flat unsatisfactory field emergence are manifold:

1. Grains cannot be found

- Wrong seed disc (very large grains)

- Incorrect air pressure

2. Seedlings are lacking in rows

- Etching damage after too dense subsoil fertilisation system (incorrect setting, blunt, deformed coulters)

- Pheasant grub (typical holes in the soil)

- Damage caused by curry comb or hoe (too deep, wrong time)

- Water logging, rotting over thick tracks

- Seed coverage defective (more common in mulch sowing)

3. Wavy emergence uneven potent seedlings

- Uneven sowing depth (driving too fast, blunt coulters)

- too little germination water in the absence of soil and drought

5. Non-germinated grains, abnormal seedlings

- Unfavourable germination conditions (drought, cold)

- Cloddy seedbed (interrupted water connection, long distances for seedling)

- Interruption of the germination process by cold spell, fungal attack

- too little germination water in the absence of soil and drought

- Incorrectly superimposed residual seed (temperature, moisture, stain)

- Lack of germinability, the driving force of the seed

For the stock control, suitable tools must be available: Trowel or shovel, yardstick, floor probe.

4. Seedlings developed very differently

- To loose seedbed (poor germination water supply)

- Cloddy seedbed (interrupted water connection, long distances for seedling)

- Grains placed too deep

- Grain spilled (for example, siltation of seed furrows too deep)

- Lack of air after siltation, water logging

- Grub damage on the maize (wire worm, centipedes, snails)

- Fungal infection (more common in long rise times after early seed corrosion protection)

- Long dwell time of un- and germinated maizes in wet, cold soil

- Plants and many weak double plants and holes after rolling the grains (vehicle speed is too high, blunt sowing coulters)