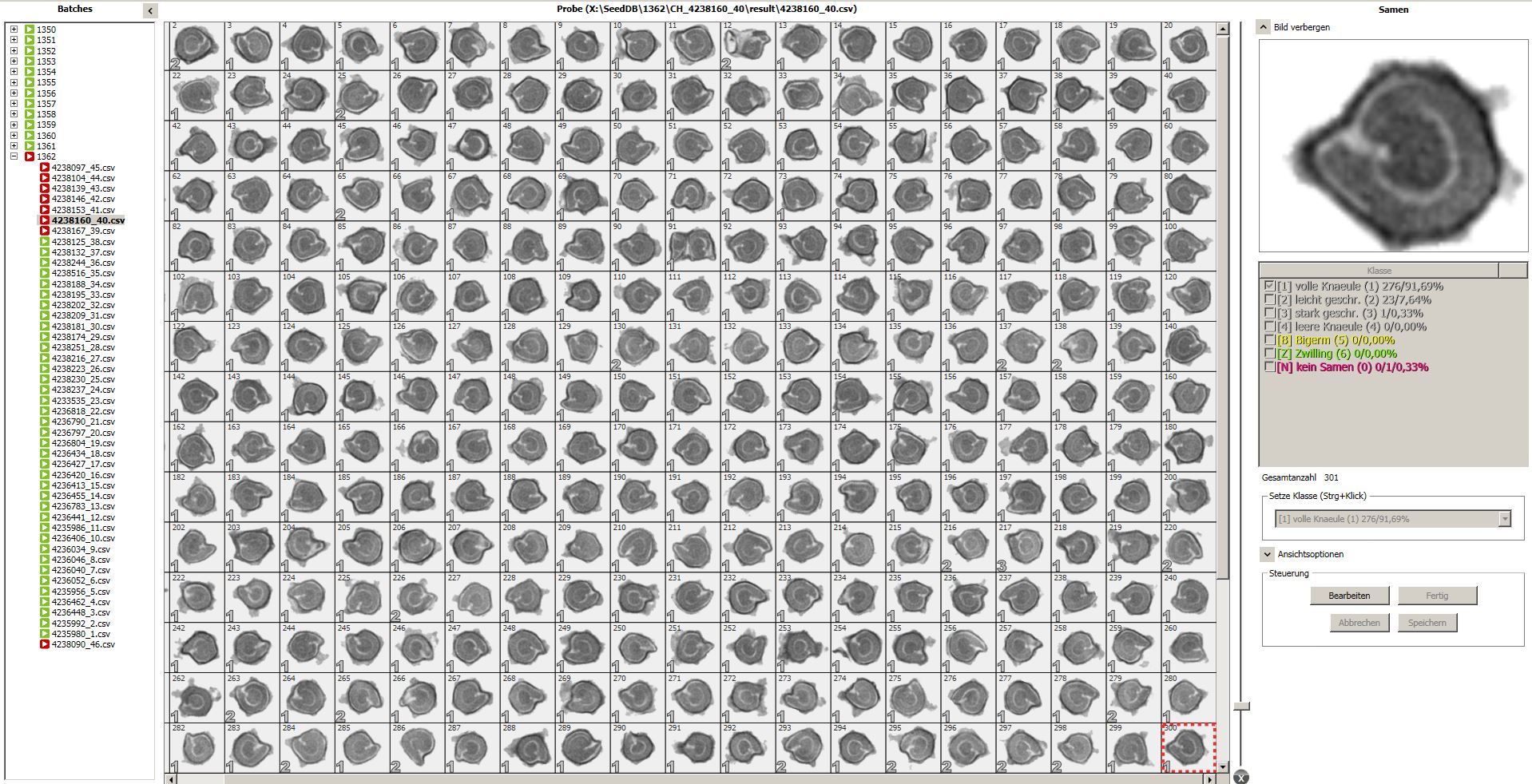

Each batch is examined individually

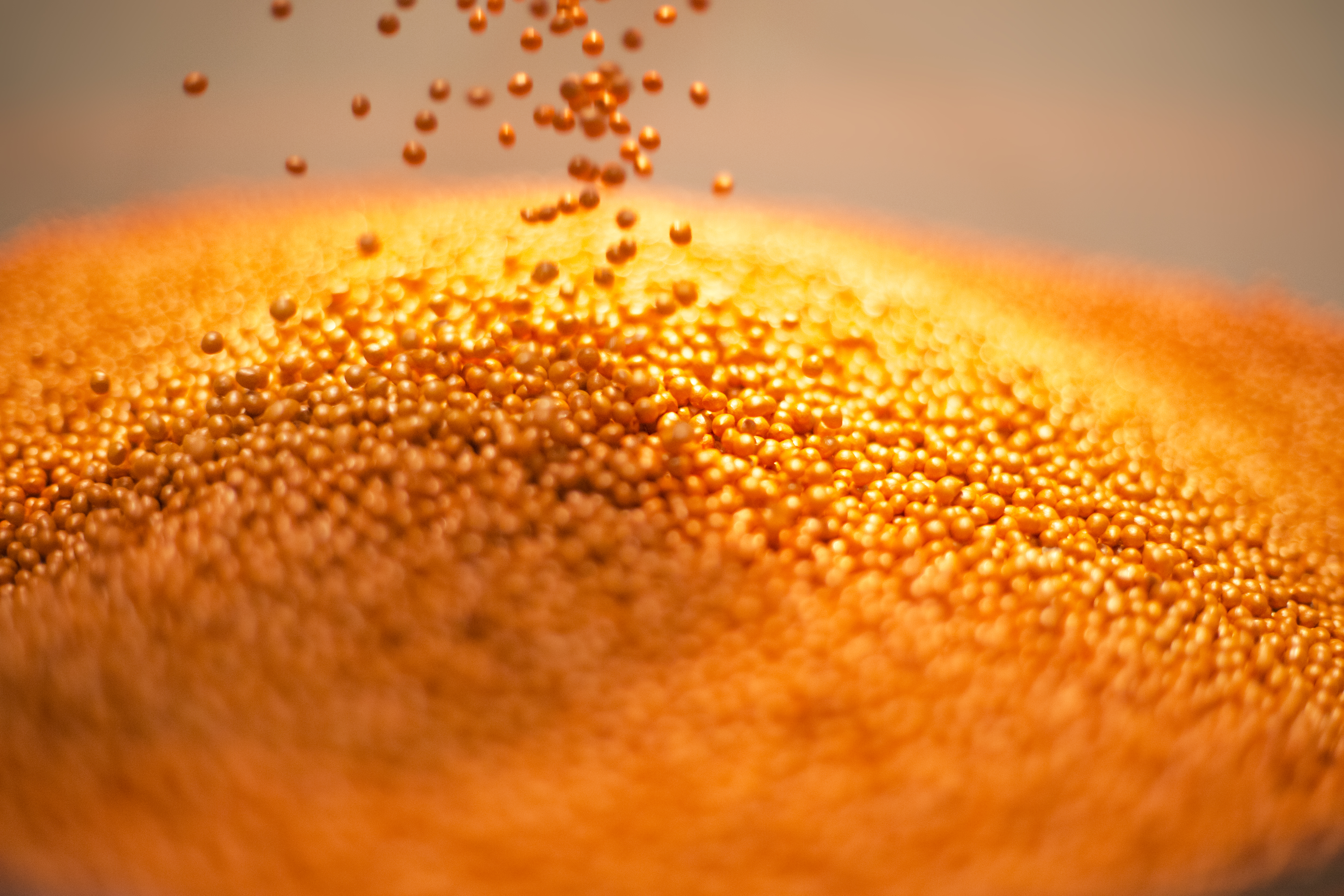

Instead the goal is, where possible, for a single, strong plant to emerge from each seed. That is why KWS expends great time and effort to screen out unwanted seeds. After the seeds have been processed into the familiar orange pellets, just less than 30 percent of the original total are usually left over following the rigorous selection process. To control the process as well as possible, each batch is examined individually. The computed tomography scanner helps the experts in the seed quality lab.

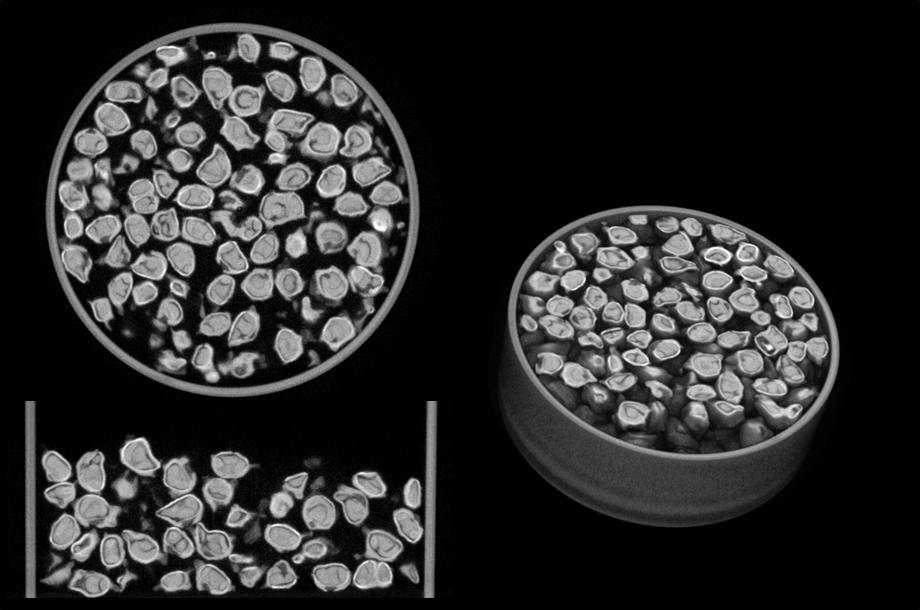

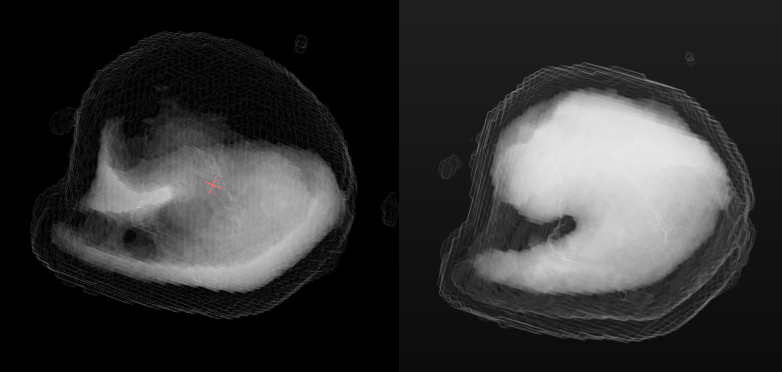

The KWS expert Olaf Brinkmann opens the door to an austerely equipped laboratory room. A device developed by the Fraunhofer Society and about two cubic meters in size is located there. Only a handful of these “Seed Inspectors” are in use worldwide. The interior houses a weak source for X-rays and, opposite it, an X-ray detector. Installed between them are a small electric turntable and a robotic arm