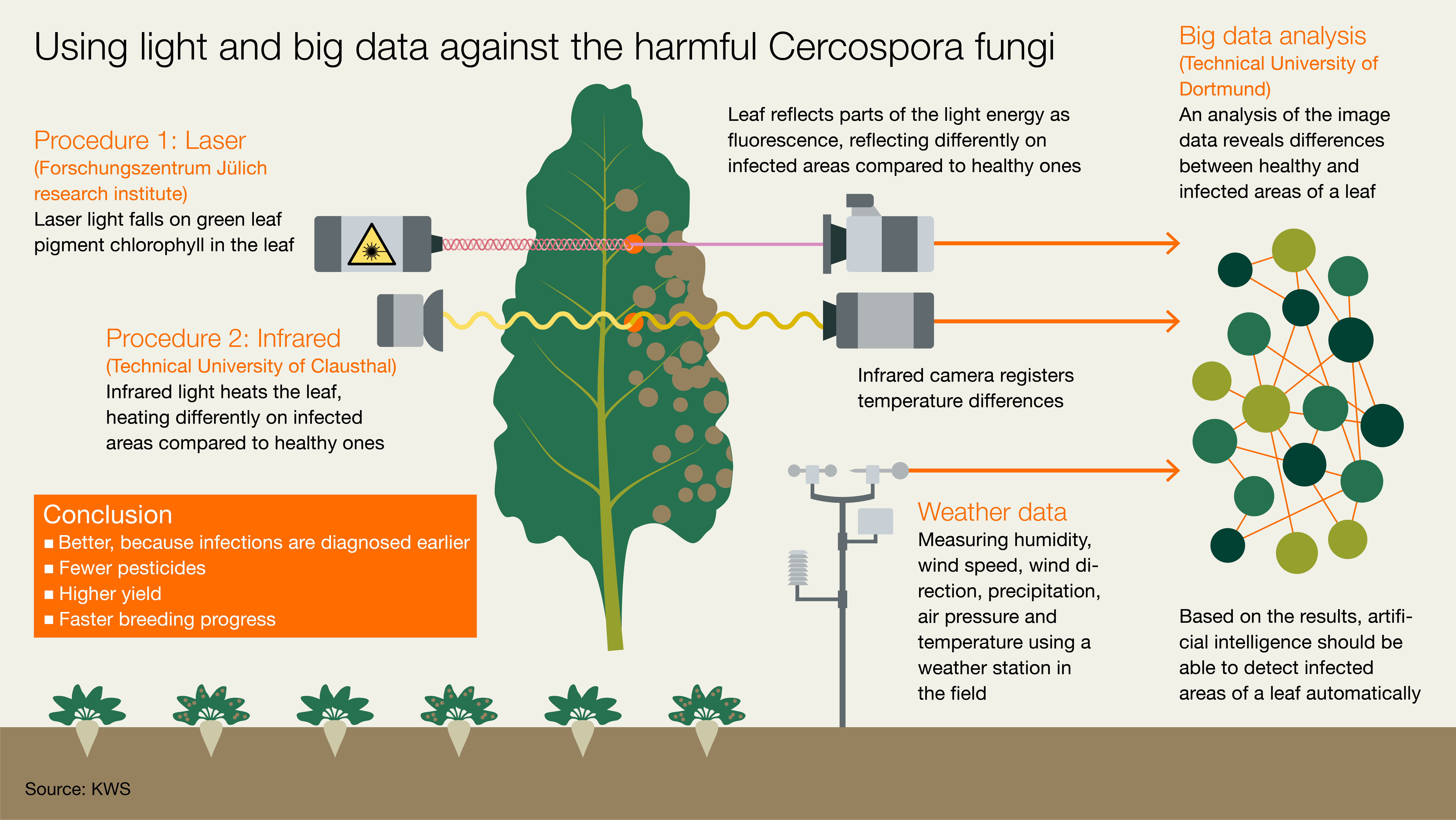

Battling the harmful Cercospora fungus with big data, light and artificial intelligence

The earlier Cercospora leaf spot is stopped, the fewer the losses that sugarbeet farmers will suffer. In the “DataPlant” project, three research institutions and companies are combining their farming and optics expertise in an effort to automatically spot the fungus at an early stage – with the help of light, sensors, weather data and artificial intelligence.

The project partners:

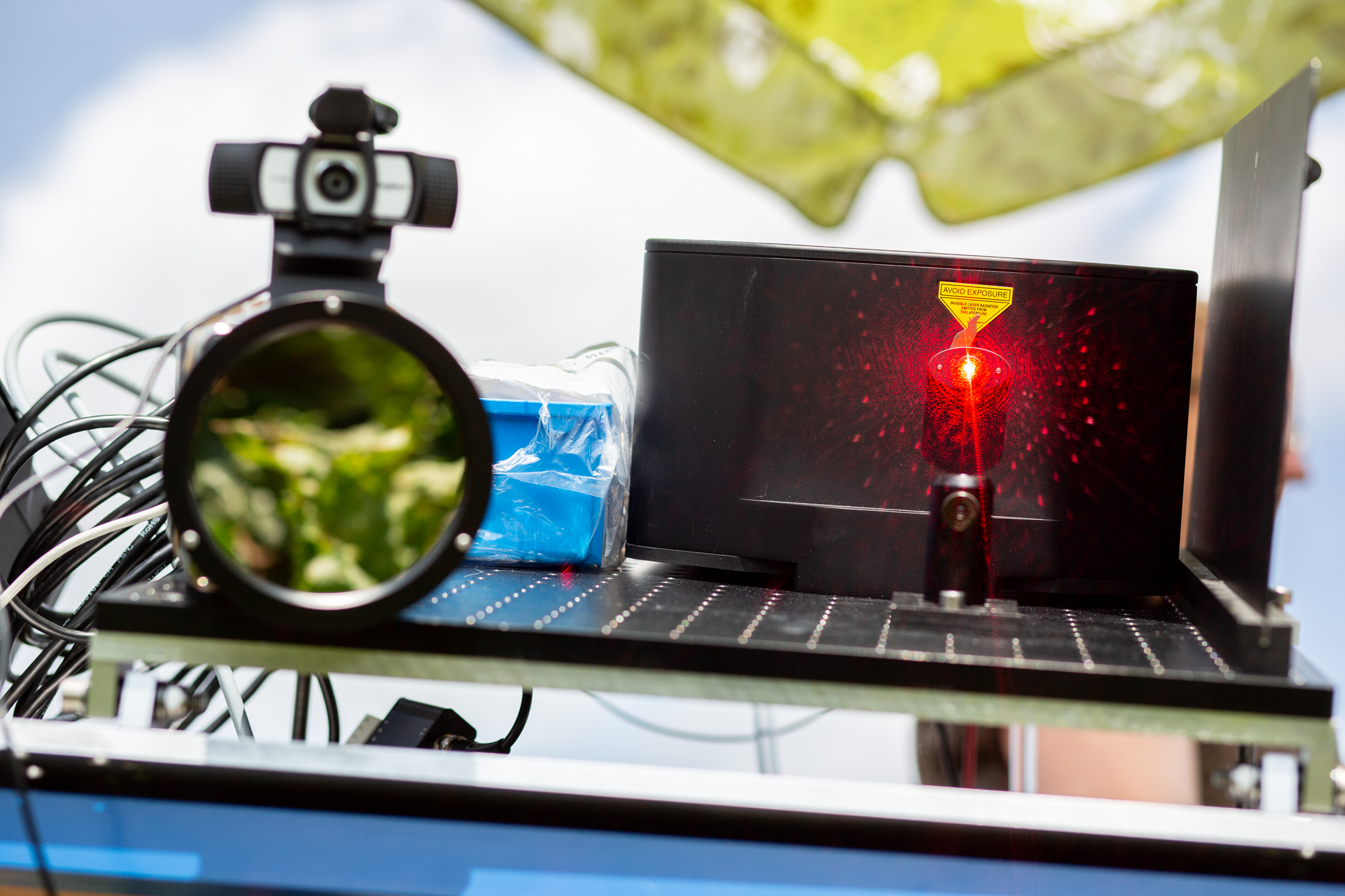

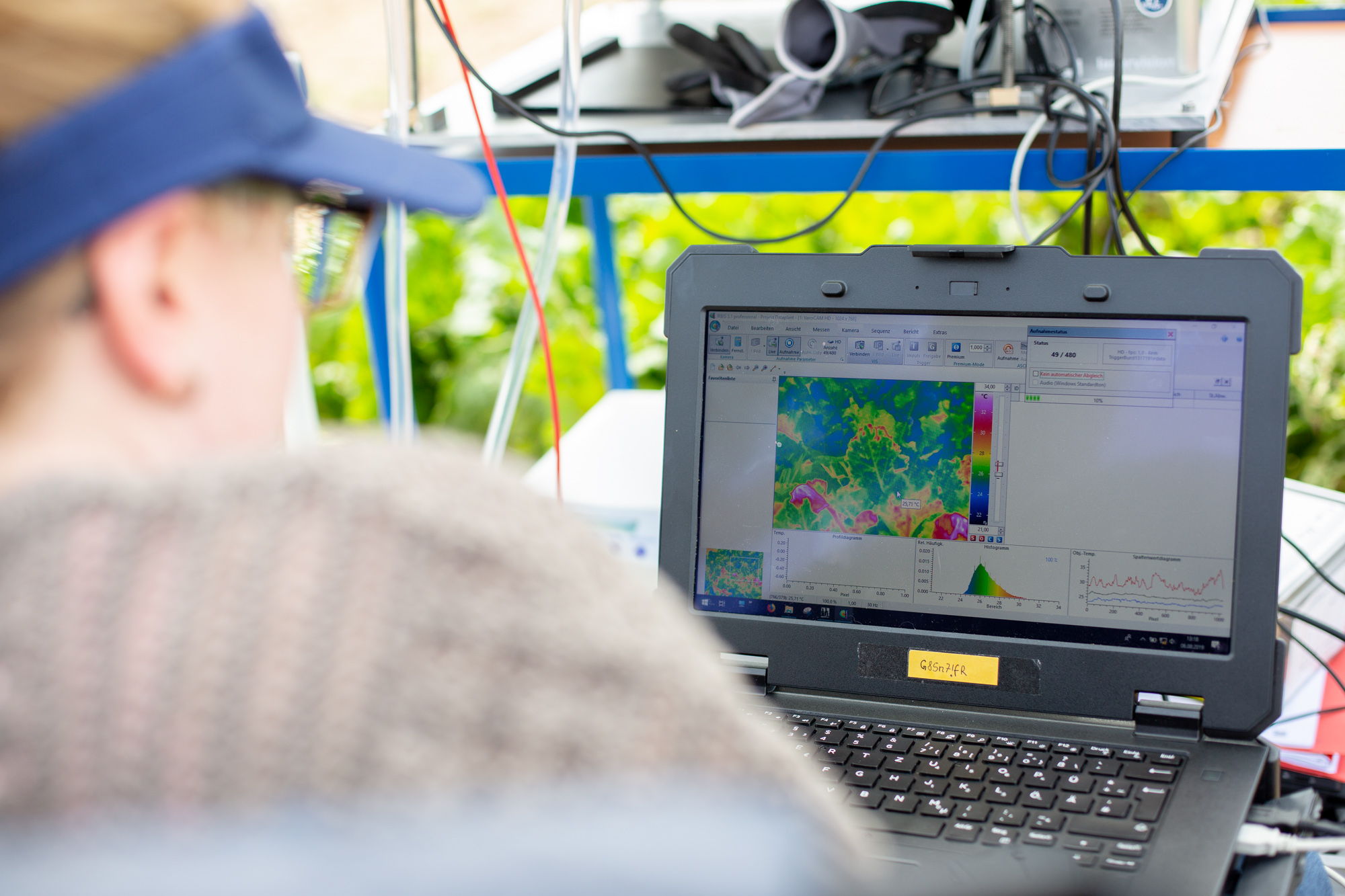

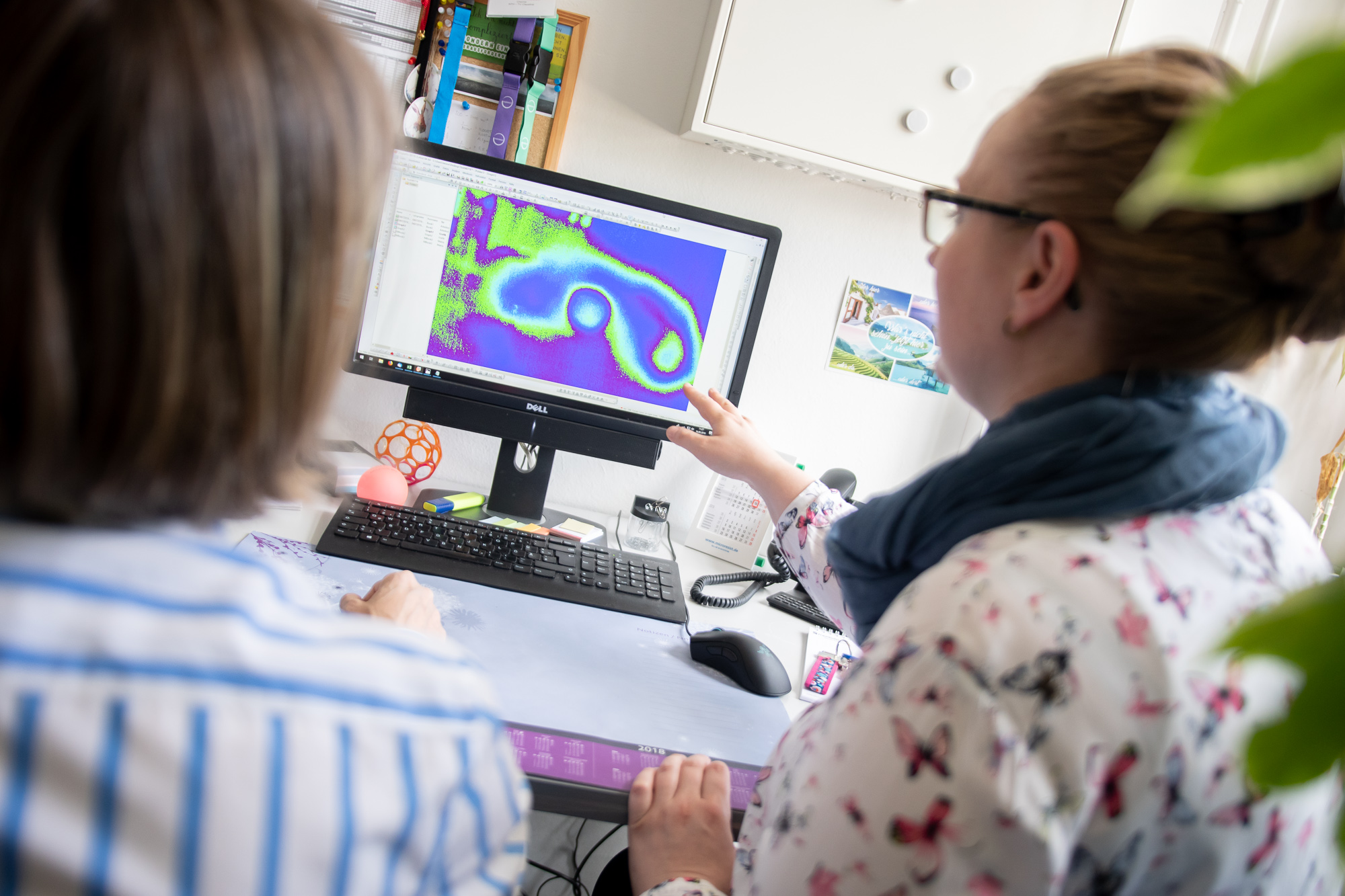

The DataPlant project is being funded by the German Ministry of Food and Agriculture. Why? The key reason is that the project is being conducted by a consortium of leading institutions and companies in Germany that are involved in the complex area of “digitalization of agriculture.” In addition to KWS, the group consists of seed experts, physicists at the Technical University of TU Clausthal, phenotyping experts at the Research Center of Jülich and computer scientists at the Technical University of Dortmund who have joined KWS in the investigation of new data-analysis opportunities. The project also includes the companies Infratec and MG Optical Solutions for sensor and measurement technology as well as experts from BASF Digital Farming.

Discover more

Your contact person