The sugar beet for feed. Makes feed sugar beet look old—the new perspective on cattle feed

With its high dry matter yield, high energy content and good palatability, KWS Feedbeets are a valuable in-house basic feed. With this basic feed, you gain greater independence from concentrated feed and a useful supplement for protein-rich and low-energy rations.

The cost of feed alone accounts for around half of the production costs in German milk production. Thus, rationing cost savings, increasing the in-house basic feed share and improving feed conversion can have a positive and rapid impact on operational performance. In order to support you in increasing your operational performance, we offer you KWS Feedbeet high and stable yields for dairy and beef cattle feed. In principle, all KWS beet varieties are suitable both for use as a biogas substrate and as KWS Feedbeet. What began with the use of biogas now gains a new dynamic with the use as Feedbeet, so that the beet is indispensable as feed for cattle on many farms.

The cows love the sweet taste of the sugar beets. Even if they are no longer hungry, they still like to feed on Feedbeet!

KWS Feedbeet - advantages at a glance

KWS Feedbeet offers you a new perspective on ruminant feeding through:

- High and stable yields

- Very good palatability

- Improvement in milk quality (milk fat and protein)

- Increase in the energy intake from the forage

- Reduction of power feed use

- Easily digestible and energetic

- High TS content and low soil adhesion

Our download for feed beet

Field report by farmer Klaus Schröder

| Location | Lower Saxony, Germany |

| Company size | 310 ha |

| Cultures | 70 hectares of grassland, 240 hectares of arable land (of which 35 hectares KWS Feedbeet) |

| KWS Feedbeet | Cultivation since 2014 |

| Livestock | 170 dairy cows |

| Species | Holstein-Friesian |

| Ø milk yield/cow/year | 10,300 kg |

| Ø Milk fat content | 4.3% |

| Ø Milk protein content | 3.6% |

The use of KWS Feedbeet as feed started in 2014 after Mr Schröder heard that sugar beets had been used as feed in Denmark for many years. "What the Danes can do, we can do too," were his words, and off they went. It started with 4 kg of silaged beets/cow, which, to avoid selections, was added chopped into the feed mixer wagon. The beets came from the whole beet silage for the biogas facility and were thus quickly available. The effects were not long in coming. Even with the small amount of beets, there was a significant increased in milk fat (on average by 0.2% points) and milk protein (on average by 0.3% points). Having become more courageous, Klaus Schröder then increased the quantity to 6 kg of fresh beets. However, one could not dare go higher at first.

Then came the excursion to Denmark...

In the summer of 2015, Klaus Schröder and other farmers went on an excursion with KWS to Denmark. During the tour, several farms were visited, some of which fed up to 24 kg of fresh beets. It also became clear that every farm used a different method of feeding and silaging—the standard solution was not there either. Klaus Schröder was very impressed by the experience: "They fed more than one bucket of sugar per animal per day! Truly amazing!!"

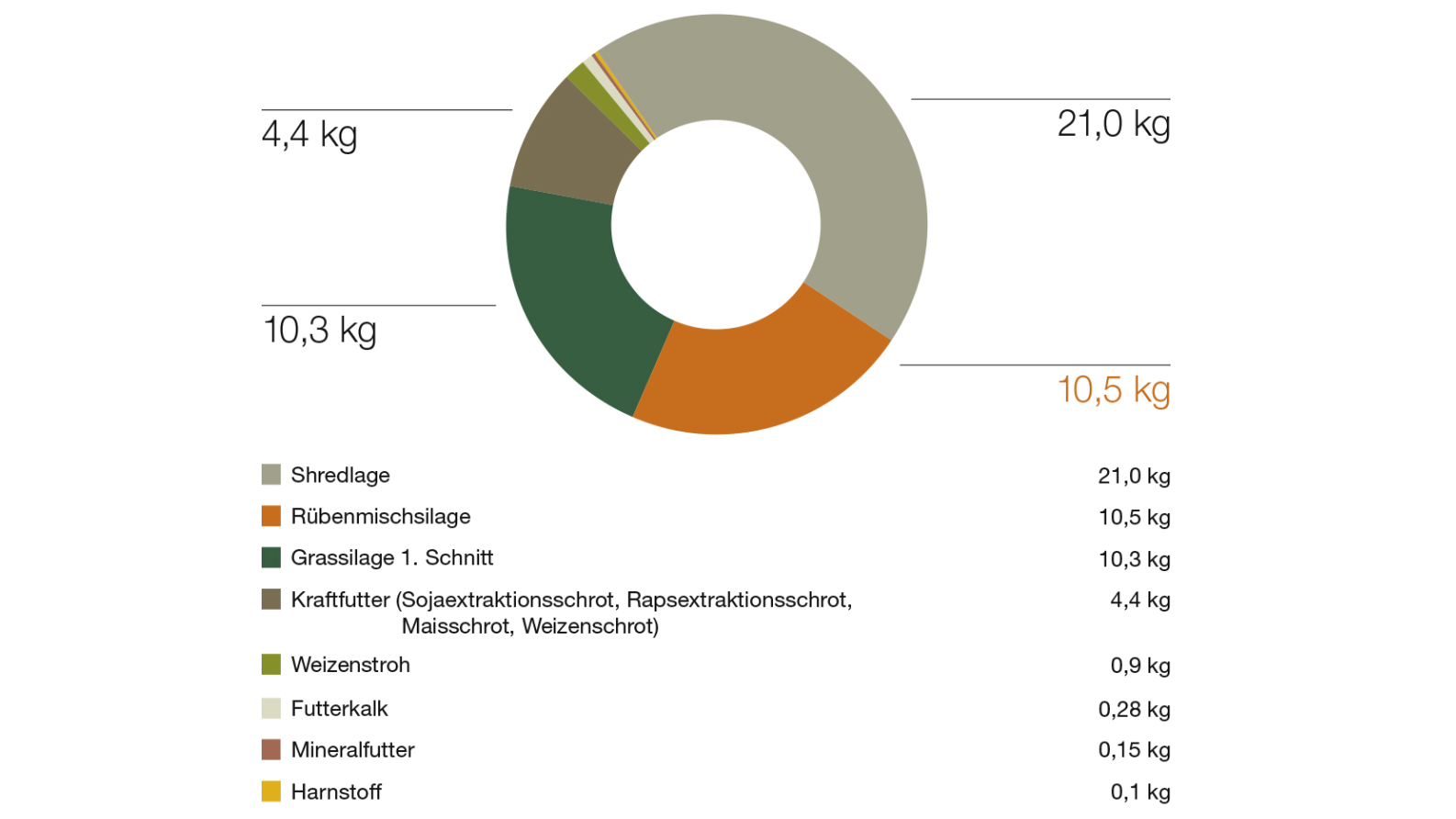

When he arrived home, Klaus Schröder also wanted to know and increased his beet share in the ration to 12 kg fresh mass/cow. This also worked without problems during feeding. Although a further increase in the amount of beet is currently desired, attention must be paid here to the willingness of the cows to run to the milking robot. A careful adjustment of the energy density in the base ration is important, as the robot acceptance decreases as the mixture becomes too rich. This depends on the overall performance and should be monitored further.

In order to have feed with beets with consistent quality throughout the year, in November Klaus Schröder decided to incorporate the beets together with grass silage and dried sugar beet pulp. For this purpose, the beets were shredded with a sugar beet pulp scoop and mixed with grass silage (3rd cut) and dry beet pulp mixed in the feed mixer. With everything pushed up in silo and covered, the feed was finished for the entire season. In the silo itself, Klaus Schröder has created two different mixing ratios. The front mixture contains 68% beets, 7% grass silage and 25% dry sugar beet pulp (proportions are based on fresh mass weights). Further back in the silo, the mixture is 64% beet, 20% grass and 16% dry sugar beet pulp.

A special feature for Klaus Schröder with the beet is the harvesting time. Here it is crucial to dig up as late as possible in order to generate the maximum yield. Therefore, he really likes the ensilage with grass silage at a later date.

He is not worried about the soil adhesion. It is important that the sugar beets are cleared as much as possible under dry conditions and then stored for a good week at the edge of the field in the clamp. This is how the sugar beet dries up, and possibly adhering soil can chip off during the subsequent loading by loading mouse or loading belts. The proportion of earth after loading is about 0.5% for Mr Schröder’s sugar beet.

It is important to think about correct destoning before using sugar beets. With a few stones, a beet pulp scoop is sufficient; with many stones, you have to switch to other devices already on the market.

You might also be interested in...

Expert knowledge of farming, from sowing to harvesting

From sowing to harvesting, KWS advises you on important agricultural issues. In addition to our useful tools and calculators, we have combined our expert knowledge and experience with sowing, plant growth management or harvesting to support you in your decision-making.

Continue reading