Sugarbeet harvest

The goal of sugarbeet growing lies in getting the washed beet harvest with as little loss as possible into the sugar refinery or biogas plant and therefore secure maximum added value creation.

Information on sugarbeet harvest – harvest date and harvester technology

Harvest date of the sugarbeet

Before starting the sugarbeet harvest, an uprooting sequence should be determined. The following applies here:

- Uproot “weaker“ types first as the yield increase for “good and health” stocks is significantly higher

- Use of dry days as moist conditions may cause structural damage, increased dirt tare and more beet casualties due to increased cleaning intensity

- Using wide tyres and/or tyre pressure regulation systems, the ground can be protected during harvest, ride comfort increased and fuel consumption reduced (also beet lifters with track options are being used in a wide range of applications)

- Observe subsequent crop

Uprooting technology for sugarbeet

In order to achieve high-quality and low-loss uprooting, you should observe the following test criteria during harvest:

The following are to be examined:

- Diameter of the tops

- Uprooting shares

- Depth adjustment

- Driving speed

- Cleaning intensity

The following should also be checked:

- Soil protection: Wide tyres, tyre pressure regulation systems or tracks

- Adapt driving speed to the harvest in order to prevent losses due to root fracture

- The biggest losses result from beets being topped too low and root fracture

Defoliate or top?

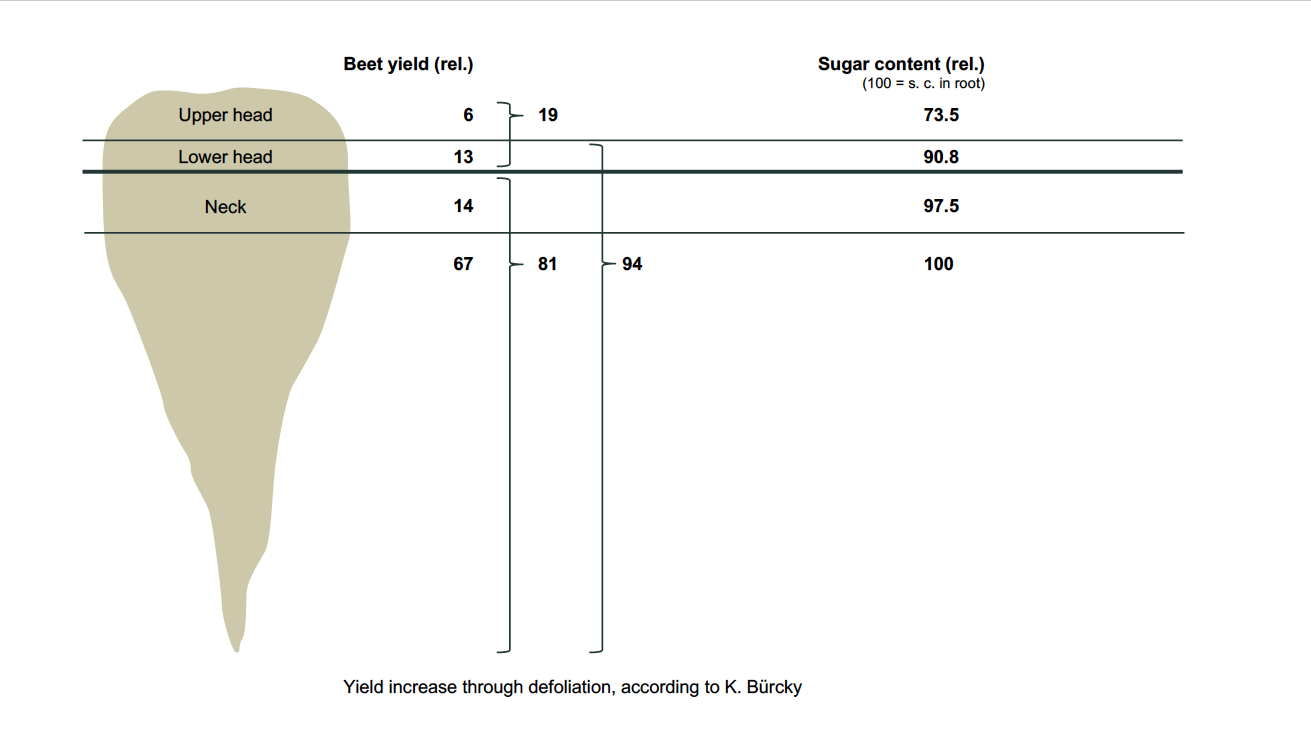

More yield through defoliating!

- Technical solutions for defoliation have been developed over the past few years by various robot manufacturers

- The defoliation method lends itself well for sugarbeets for biogas usage and results in increased yields

- Beets are not topped but only defoliated and harvested along with the head

- Several yields of 5–10 % (Beer and Michiels-Corsten, 2009) are possible